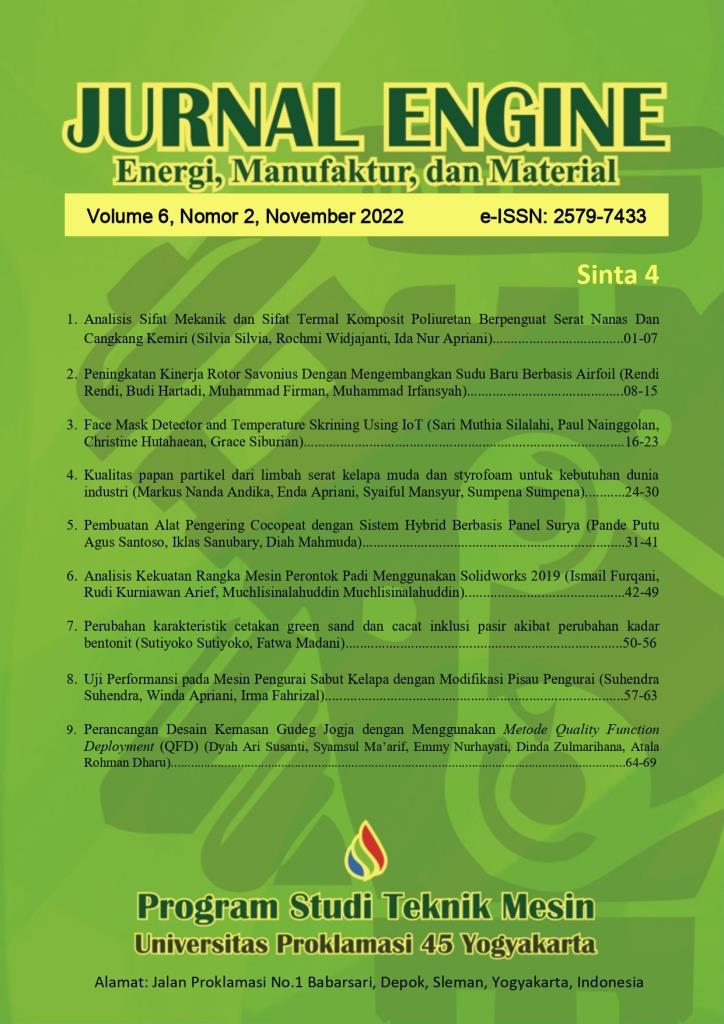

Kualitas papan partikel dari limbah serat kelapa muda dan styrofoam untuk kebutuhan dunia industri

DOI:

https://doi.org/10.30588/jeemm.v6i2.1165Keywords:

waste, coconut fiber, styrofoam, particleboard, industryAbstract

Waste of young coconut fiber can potentially be used as reinforcement for new particleboard material. This potential agricultural waste is quite large in Indonesia. Styrofoam waste is also a problem to date. This is because the use of styrofoam as a food wrapper is still quite high in Indonesia. Besides being environmentally friendly, this particleboard also has economic value in the industrial world. Young coconut waste is crushed with a coconut fiber decomposing machine. Styrofoam as an adhesive is dissolved with gasoline. Each proportion of raw material for young coconut fiber: styrofoam, which is 25: 75 (%), 50: 50 (%), and 75: 25 (%).

The test results of the mechanical properties of the particleboard with Composition III showed better results than the particleboard with Composition I and Composition II, which obtained an average MoE value of 832.69 kgf / cm2, an average MoR value of 12.10 kgf / cm2, and the average IB value of 2.01 kgf / cm2.

References

Apriani, E. (2017). Analisa Pengaruh Variasi Komposisi Bahan Limbah Dari Serat Kelapa Muda, Batang Pisang Dan Kertas Bekas Terhadap Kekuatan Bending Sebagai Papan Komposit. Jurnal ENGINE; 1 (2): pp no. 38-46, e-ISSN 2579-7433.

Asfarizal. (2016). Karakteristik Komposit Berbasis Serat Kelapa Dan Berbasis Serat Aren. Jurnal Teknik Mesin; Vol. 6 (1): hal 24-31, ISSN: 2089-4880.

Muqtadi, K. (2014). Dampak Penggunaan Dan Analisa Pengaruh Styrofoam Sebagai Substitusi Pasir Dengan Bahan Tambah Plastiment-Vz Terhadap Nilai Kuat Tekan Beton. Jurnal Teknik Sipil dan Lingkungan; Vol. 2 (2).

Nurhajati, D.W., dan Indrajati, I. N. (2011). Kualitas Komposit Serbuk Sabut Kelapa Dengan Matrik Sampah Styrofoam Pada Berbagai Jenis Compatibilizer. Jurnal Riset Industri; Vol. (2): Hal 143-151.

Purwanto, D. (2016). Sifat Fisis Dan Mekanis Papan Partikel Dari Limbah Campuran Serutan Rotan Dan Sebuk Kayu. Jurnal Riset Industri; Vol. 10 (3): hal. 125-133.

Sari, N. H., Sinarep, Taufan, A., & Yudhyadi, IGNK. (2011). Ketahanan Bending Komposit Hybrid Serta Batang Kelapa/Serat Gelas Dengan Matrik Urea Formaldehyde. Jurnal Ilmiah Teknik Mesin Cakra M; Vol. 5 (1): hal 91-97.

Septiari, I. A. P. W., Karyasa, I. W., & Kartowarsono, N. (2014). Pembuatan Papan Partikel Dari Limbah Plastik Polyprophylene (PP) Dan Tangkai Bambu. E-Journal Kimia Visvitalis Universitas Pendidikan Ganesha Jurusan Pendidikan Kimia; Vol. 2 (1).

Sudarsono, Rusianto, T, & Suryadi, Y. (2010). Pembuatan Papan Partikel Berbahan Baku Sabut Kelapa Dengan Bahan Pengikat Alami (Lem Kopal). Jurnal Teknologi; Vol. 3 (1), hal 22-32.

Soekardi, Y. (2012). Pemanfaatan & Pengolahan Kelapa. Bandung: Yrama Widya, ISBN 978-979-077-427-8.

Sudipta, I. G. K & dan Sudarsana, K. (2019). Permeabilitas Beton Dengan Penambahan Styrofoam. Jurnal Ilmiah Teknik Sipil; Vol. 13 (2).

Wibowo, H. (2008). Studi Banding Konduktifitas Panas Antara Gabus (Styrofoam) Dengan Sekam Padi. Seminar Nasional Aplikasi Sains Dan Teknologi. Yogyakarta.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Engine: Energi, Manufaktur, dan Material agree to the following terms:

Authors retain copyright and grant the Jurnal Engine: Energi, Manufaktur, dan Material right of first publication with the work simultaneously licensed under a Creative Commons Attribution 4.0 International License that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material) the work for any purpose, even commercially with an acknowledgment of the work's authorship and initial publication in Jurnal Engine: Energi, Manufaktur, dan Material. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Engine: Energi, Manufaktur, dan Material. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).