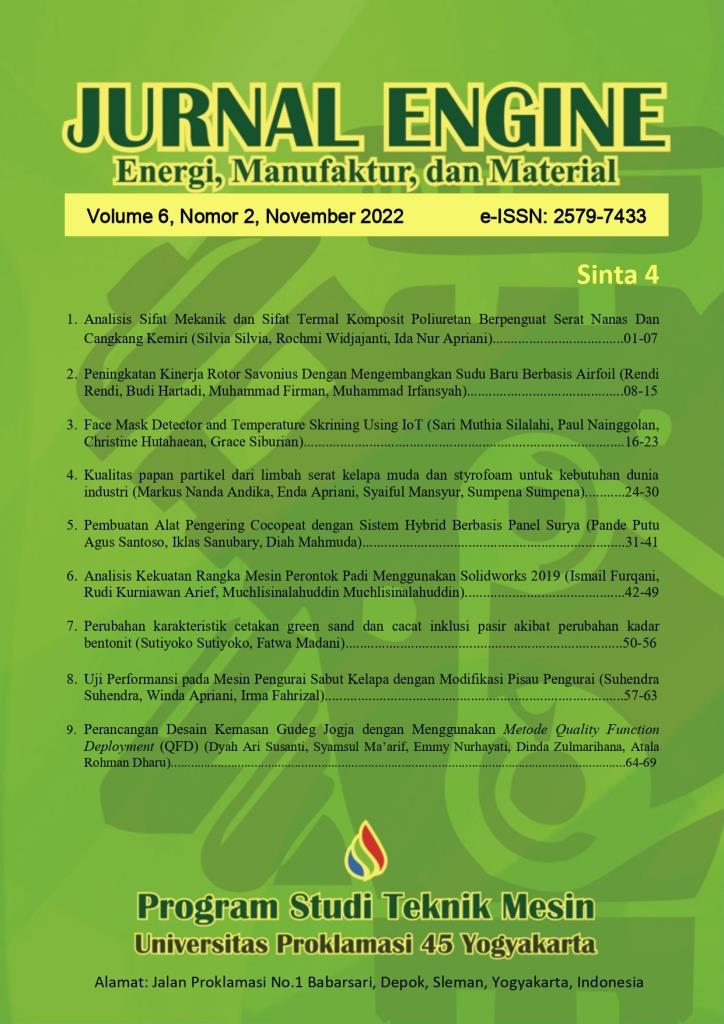

Uji Performansi pada Mesin Pengurai Sabut Kelapa dengan Modifikasi Pisau Pengurai

DOI:

https://doi.org/10.30588/jeemm.v6i2.1239Keywords:

coco fiber, cocopeat, chopper machine, chopper blade, coconout coirAbstract

Coconut coir can be processed into cocopeat and coco fiber. In the chopping process, the chopping mechanism has a critical role that will determine the results of the chopping off of coconut coir. Based on these conditions, in this study, the development of a chopping mechanism was carried out by modifying the chopper blade to improve the chopper of coconut coir. The purpose of this study was to modify the coconut coir chopper blade, perform performance tests and calculate the increased performance after modification. Modification of the chopper mechanism on the coconut coir chopper machine is done by replacing the type of chopper blade with an iron rod with a diameter of 4 mm which is sharpened at the end. The test data includes data on the capacity of coconut coir chopping, the percentage of cocopeat, the percentage of coco fiber, the percentage of unprocessed coconut coir, the percentage of material loss, and the increase in performance after modification. The modified coconut coir chopper mechanism has specifications of 240 mm long, 100 mm diameter, 39 blades, and ± 14 mm high. The test was carried out at a rotary speed of the chopper mechanism of 720 rpm. Based on the test result, the capacity of chopping coconut coir using a modified coconut coir chopper machine is 7,93 kg/hour, producing 45,57% cocopeat, 36,15% coco fiber, 13,15% coconut coir unprocessed and the loss reached 5,13%. Modifications on the chopper blade are proven to increase the performance of the coconut coir chopper machine by 297%.

References

Amin, M., & Samsudi. (2010). Pemanfaatan Limbah Serat Sabut Kelapa sebagai Bahan Pembuat Helm Pengendara Kendaraan Roda Dua. Prosiding Seminar Nasional Unimus, 314–318.

Anjiu, L. D., Suhendra, & Fahrizal, I. B. N. (2021). Rancang Bangun dan Uji Performansi Alat Pembuka Katup Menggunakan Mekanisme Tuas. Jurnal Engine, 5(2), 45–52.

Apriani, E., & Nurusman, H. A. (2019). Perancangan Alat Pengurai Sabut Kelapa Untuk Dunia Industri Skala IKM (Industri Kecil Dan Menengah). Prosiding Nasional Rekayasa Teknologi Industri Dan Informasi XIV, 2019(November), 386–391.

Arfittariah, Zain, A., & Akbar. (2021). Rancang Bangun Mesin Otomatis Pencacah Mini Serabut Kelapa (Mesin Cocopeat). Jurnal Nasional Komputasi Dan Teknologi Informasi, 4(6), 517–521.

BPS Provinsi Kalbar. (2021). Provinsi Kalimantan Barat Dalam Angka 2022. Pontianak: BPS Provinsi Kalimantan Barat.

Ditjenbun. (2020). Statistik Perkebunan Unggulan Nasional 2019-2021. Jakarta: Direktorat Jenderal Perkebunan, Kementerian Pertanian Republik Indonesia.

Gafur, A., & Muklis, A. (2022). Rancang Bangun Mesin Pengurai Sabut Kelapa menjadi Cocopeat dan Cocofiber. Dinamika Vokasional Teknik Mesin, 7(1), 55–61.

Indahyani, T. (2011). Pemanfaatan Limbah Sabut Kelapa pada Perencanaan Interior dan Furniture yang Berdampak pada Pemberdayaan Masyarakat Miskin. Humaniora, 2(1), 15–23.

Priono, H., Ilyas, M. Y., Nugroho, A. R., Setyawan, D., Maulidiyah, L., & Anugrah, R. A. (2019). Desain Pencacah Serabut Kelapa dengan Penggerak Motor Listrik. Jurnal Engine, 3(1), 23–28.

Santoso, P. P. A., Sanubary, I., & Mahmuda, D. (2021). The Effect of Blade Density Variation to Cocopeat Mass that Produce by Poltesa Cocopeat Machine. Laporan Penelitian Politeknik Negeri Sambas, Sambas.

Satito, A., Hariyanto, & Supandi. (2020). Rancang Bangun Mesin Pengurai Sabut Kelapa Menjadi Cocopeat dan Cocofiber dalam Upaya Penganekaragaman Produk pada Kelompok Tani “Sumber Rejeki.” Prosiding Seminar Nasional Polines, 711–722. Semarang: Politeknik Negeri Semarang.

Suhendra, Hardi, Y., Nopriandy, F., & Fahrizal, I. (2020). Rancang Bangun Mesin Perontok Lada (Piper Nigrum L.) Tipe Silinder Perontok Berjaring. Jurnal Teknologi Pertanian Andalas, 24(1), 17–22.

Syahputra, M. (2020). Pembuatan Mesin Pengurai Sabut Kelapa. Universitas Muhammadiyah Sumatera Utara.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Engine: Energi, Manufaktur, dan Material agree to the following terms:

Authors retain copyright and grant the Jurnal Engine: Energi, Manufaktur, dan Material right of first publication with the work simultaneously licensed under a Creative Commons Attribution 4.0 International License that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material) the work for any purpose, even commercially with an acknowledgment of the work's authorship and initial publication in Jurnal Engine: Energi, Manufaktur, dan Material. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Engine: Energi, Manufaktur, dan Material. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).